Don’t Toss Those Parts! Let Our Precision Machining Experts Rework Them Instead

If our precision machine shop ever makes a mistake, we make it right—no question. But what if you (the customer) or someone on your team makes a mistake that results in an issue with your parts? An incorrect callout, a miscalculated tolerance, a part number error: what happens then?

Some shops will require you to place an entirely new order. But here at Accurate CNC Services, we do our best to safeguard your budget and timeline. Whenever possible, we don’t remake your parts from scratch; instead, we rework them using a combination of ingenuity and expert precision machining capabilities.

Reworking vs. Remaking Manufactured Parts

Not every mistake can be corrected through reworking. For instance, if you requested the wrong material, there’s no “easy button” that turns aluminum into stainless steel. But we’ve successfully reworked many parts to address smaller errors, saving our customers time and money.

1. Reworking a design mistake

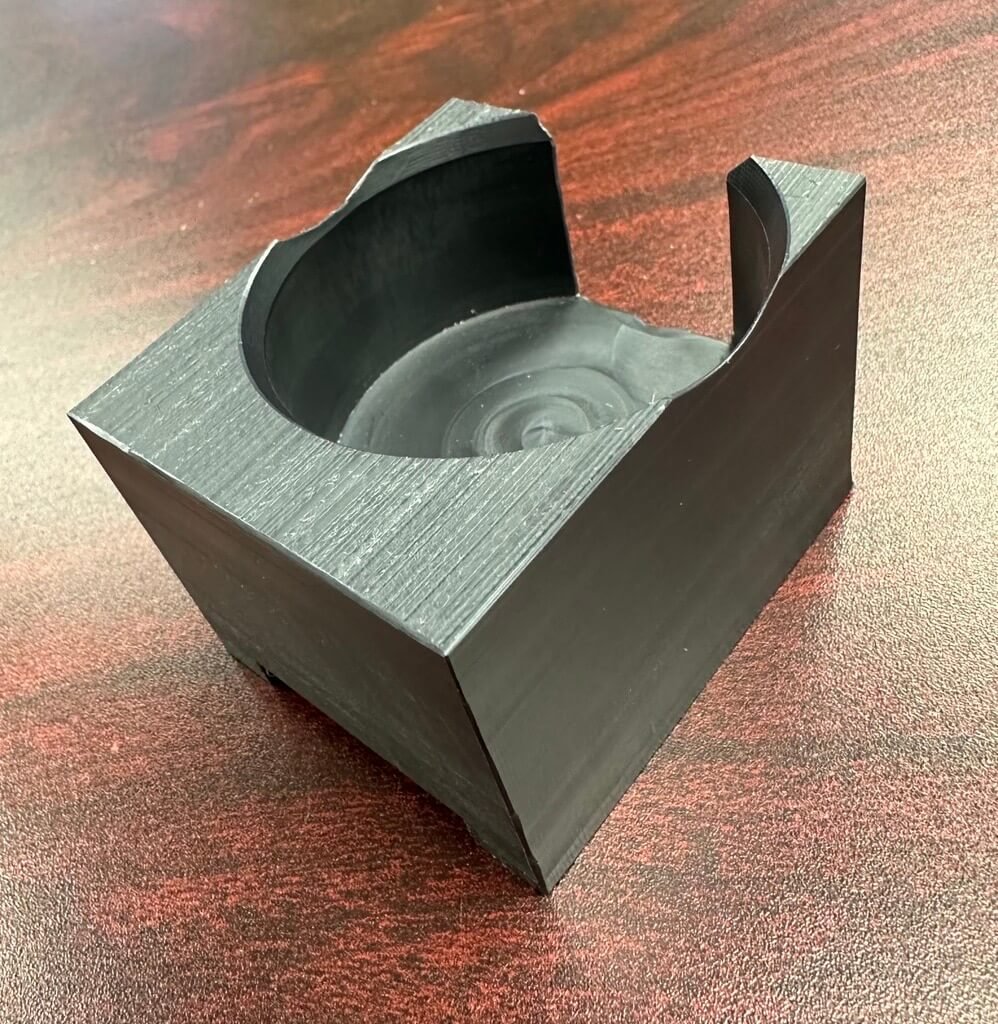

Challenge: After fully completing a beverage packaging order, our customer discovered a mistake in their design. All 110 pieces were affected, and remaking these parts from scratch would have been quite costly for our customer.

Solution: To avoid starting over, our team unearthed a solution for re-machining the parts, opening up the slot on the bottom of each part to correct the issue.

2. Reworking an incorrect part number

Challenge: When an engineer transcribed the incorrect part number for laser engraving services, our customer assumed they would need to pay us to remake their spreader bars. We countered with a suggestion that we simply rework the part—a faster and less expensive alternative.

Solution: To solve the problem, we ground down the incorrect part number, precision machining a shallow recess before laser engraving the new (correct) part number.

We’re incredibly proud to say that we were able to rework the entire part order with fresh laser engraving for nearly the same cost as making ONE all-new part. How’s that for keeping costs low?

3. Reworking missized tapped holes

Challenge: When a customer received their UHMW parts with numerous 1/4-28” tapped holes, they realized their mistake: they should have requested 1/4-20” holes. Unfortunately, the customer could not get different-sized fasteners to fit the holes, leaving them to believe they would need to have the parts remade.

Solution: Instead of remaking the parts, we drilled out the tapped holes and placed 1/4-20” Heli-Coils in each part, recovering the parts’ usability and saving the day for our customer.

4. Reworking outdated inventory

Challenge: Due to major industry disruptions caused by the pandemic, our OEM customer had a significant inventory of motor mount plates for an in-house machine—but the motor itself wasn’t available, rendering the plates obsolete.

Solution: Rather than create all new parts, our team drilled a new hole pattern and added slots to the outdated motor mount plate, allowing the plates to be repurposed for a different replacement motor.

Our Smart Manufacturing Solutions Help You Save Time and Money

When we all work together to identify issues and solve problems, everyone wins.

Before tossing parts in the trash, talk to the team at Accurate CNC Services. If we can rework your parts successfully, we will!

Request a secure, simple quote for precision machining, laser engraving, or other services!