Think Your Part is Too Big For Our Laser Cutting Services? Think Again

One thing you're unlikely to hear at our Idaho machine shop: “Sorry, that part is too big for our laser cutting services.” Not only does our Thunder Nova 63 feature a 63" x 39" table, but we can often handle parts that are twice that length or longer.

Between our machine's passthrough capabilities and our team's creative problem-solving approach, there are rarely times when a part is considered too large for our in-house laser cutting. Discover the techniques we employ to help ensure our customers get the parts they need, no matter the size.

A Case Study in Laser Cutting Oversized Parts

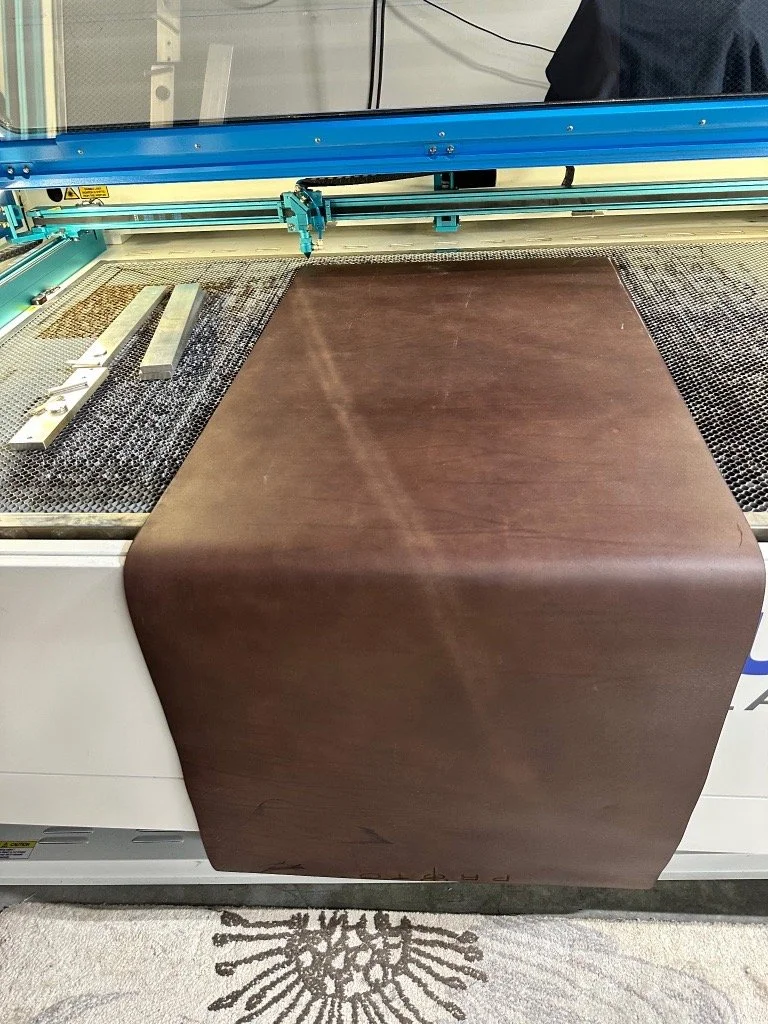

Perhaps no project better illustrates our approach to oversized parts than the custom-engraved yoga mats we recently created for a client out of actual cowhide. When the customer arrived at Accurate CNC Services with his request, we faced multiple challenges: a full cowhide doesn't fit on any standard laser table; leather curls and distorts when heated; and the length of the mat meant the material would need to be moved and realigned twice, with precision each time.

Despite these challenges, we were able to come up with a solution that worked perfectly:

First, we used chalk lines to map out where each yoga mat would fit within the hide, confirming we could get the exact size the customer needed.

Then, we placed aluminum bars on the cowhide to prevent the material from curling and to maintain a consistent focus for clean cuts.

Lastly, we used magnets to secure the material to the metal table surface, preventing the heat-induced distortion that is common with laser cutting.

Because the material for each mat was much longer than the machine itself, we relied on registration marks to maintain perfect alignment between cuts as we moved the material through the machine.

This attention to detail and precision ensured our customer got exactly what they were looking for. With the right techniques, even stretchy or uneven materials can be laser cut to specifications well beyond the machine’s table size.

No Limit To Our Laser Cutting Services

As precision machining experts, it probably goes without saying that we don’t spend much time working with leather goods! More often, the team at Accurate CNC is coming up with creative solutions to tackle oversized parts made from traditional machining materials, such as wood, metal, plastics, and foam.

While each project presents its own challenges, they all prove the same point: when it comes to our in-house laser cutting services, the table size alone doesn’t determine what is possible. Here are just a few examples of our problem-solving:

A customer wanted their family crest engraved on the paddle end of canoe oars. As you might imagine, the paddles were much longer than our laser bed. But by using our machine’s passthrough capabilities and a simple woodworking jack stand to support the overhanging end, we were able to engrave their design easily.

Large outdoor signs often exceed the dimensions of a standard laser table. When a local nursery needed eight-foot tall signs, we lasered the first four feet, then flipped the material and completed the remaining section. With registration marks ensuring perfect alignment and a jack stand supporting the extended material, the final signs showed no evidence of being produced in two passes.

Sometimes, “oversized” means endless. We produce gaskets for our own machine manufacturer, cutting them directly from continuous rolls of foam. Instead of cutting sheets and losing material to waste, we feed the roll through the passthrough and keep cutting.

The takeaway here is that whether your part is twice our table length or comes in a continuous roll, we likely have a solution. We just need to know what portion of the material actually requires precision machining.

Need Oversized Parts? Help Us Help You

We love a good challenge, and the more you can tell us upfront, the better we can serve you. Here is the type of information we’ll be looking for to determine whether our in-house laser cutting services are well suited to your needs:

Material type and size

What specifically needs lasering

Photos of your project (if available)

Remember that timing is everything. While customers often think of laser cutting or engraving as a final step, that doesn’t necessarily have to be true. If you’re working with an assembly, talk to us early in the process. We might suggest lasering individual components before assembly rather than trying to maneuver a complete unit through our machine.

The bottom line? Just because you have a large part doesn’t mean that our laser cutting services are off the table! Instead of being discouraged by the size, stop by our Idaho machine shop or reach out to discuss your project. With a bit of creativity, collaboration, and the right tools, we might just be able to get you the part you’re looking for.