CNC Router Services Built for Speed, Flexibility, and High-Quality Results

Our team at Accurate CNC Services thinks outside the box to support our customers. Unlike most machine shops, we offer CNC router services as a core capability, giving you faster turnarounds, improved consistency, and more manufacturing options than traditional cutting or machining alone.

Here’s exactly how our approach to routing delivers real, measurable results for Accurate CNC customers.

No Scrap Left Behind: Cutting Waste and Costs

To keep part costs as low as possible, our Idaho machine shop uses as much of every raw material sheet as possible. We even keep a lot of remnant pieces on hand, which can be a surprising help in keeping your part costs lower.

CNC routing is a great option for cutting new parts from remnants. By utilizing nearly every inch of the material, we cut down scrap, lower part costs, and support more eco-friendly production. It’s truly a win-win, and it’s one of the biggest advantages of our CNC router services.

Blanks: A Hidden Advantage

We love cutting blanks with our CNC router, both for our own jobs and for other machine shops. Router-cut blanks often require fewer operations on machining centers. And because the edge finish is machined, these blanks require less follow-up processing than blanks cut by waterjet or plasma. That’s why more and more shops come to us for this service: it’s fast, cost-effective, and saves downstream machine time.

Programming Productivity: A Stock-First Strategy to Shorten Lead Time

We program by stock material and thickness instead of by individual jobs. When we load a sheet on the router table, we don’t just cut parts for one customer. Instead, we program parts from all of our orders that use that same stock. This approach allows for:

Fewer material changeovers

More cutting time, less setup time

Faster scheduling

Quicker deliveries for customers

Our programmers even sort the master schedule by material to keep work flowing efficiently. By spending more time programming and less time changing materials, we keep your lead times as short as possible.

Nesting: Maximizing Every Sheet for Efficiency

Nesting is one of the biggest differentiators in how we use our routers. We use CAD software to optimize layout and nest every part across our open orders that use the same material and fill the entire sheet.

Cutting many parts at the same time maximizes material usage and reduces waste. This approach also lowers cost and boosts throughput by minimizing idle time, reducing setup and changeover delays, and ensuring consistent quality across all parts.

Speed Without Compromise

Our precision machine shop is always looking for ways to improve throughput without sacrificing finish or accuracy. CNC routers are one of the best ways we maximize efficiency.

One upgrade we recently made: replacing standard collet tool holders on our largest router with hydraulic tool holders. This increased rigidity and allowed for faster, cleaner cutting. And on our other routers, we take optimized, efficient cuts, enabling faster machining and requiring less labor both on and off the machine.

Engineering Creativity, Powered by CNC Router Services

Our commitment to ingenuity and problem-solving knows no bounds. Customers know we love a challenge, and routing is one of the best ways we can get creative with part manufacturing.

Because of our extensive routing experience, we’re able to stay innovative with our approach. It’s not just materials like aluminum that we put on the router. We routinely run wood, foam, and plastics.

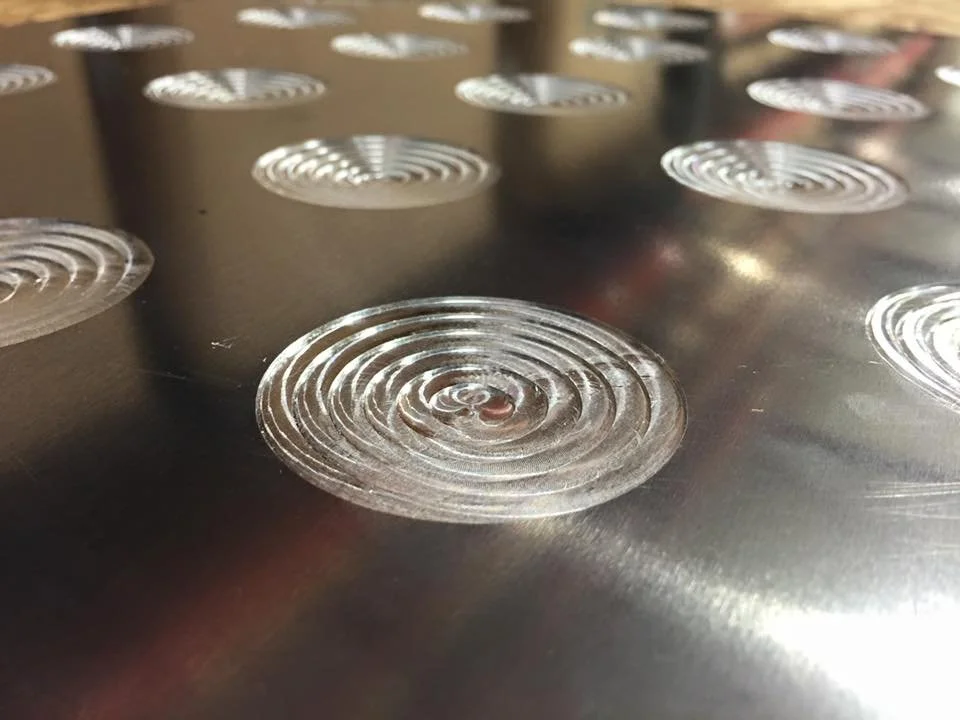

Routers aren’t limited to simple 2D work either. We often run 2.5D features and complex geometries that give customers more design flexibility.

What This Means for You

When you work with Accurate CNC, you get options that most machine shops can’t offer. Don’t be surprised if you bring us a part and we say, “Why don’t we try it on the router?” This mindset gives you:

Faster delivery

More flexibility

High-quality, consistent results

Potential cost savings

More manufacturing paths for complex parts

If you’re ready to see what our CNC router services can do for your project, request a quote today.