How We Reduce Customer Costs by Nesting Router Parts

It sounds like a sales pitch, doesn’t it? “Get more parts for less!” In this case, however, the phrase happens to be true.

We regularly apply a simple method when providing CNC router services called nesting. Nesting involves laying out flat parts to get as many pieces as possible from your sheet material.

Sounds simple, right? Yet most shops don’t offer nesting—and they certainly don’t nest parts by default!

Here at Accurate CNC Services, however, we proactively include nesting for flat parts with the same sheet material and thickness!

3 Benefits of Nesting Flat Parts for CNC Router Services

Let’s take a look at how nesting works to:

Reduce waste

Slash material costs

Get you as many parts as possible from your sheet material

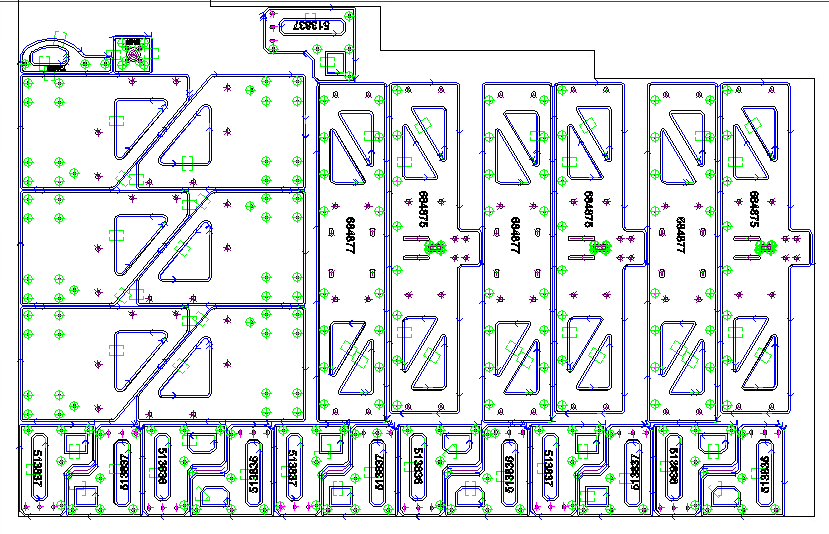

Nesting Photo #1

1. Nesting router-made parts reduces waste

Our experts leverage our router’s Enroute software to accurately nest parts very closely.

Here in Photo #1, you can see how we tightly nested the parts to maximize the available space and dramatically cut back on waste and scrap material. It’s never possible to eliminate all leftover material, but we can get close thanks to nesting!

2. Nesting flat parts helps you save money on materials

Take a look at Photo #1 again. Now visualize the number of parts that would fit on the sheet material without meticulous nesting. We would have needed at least one more sheet of material to accommodate all 22 parts.

With nesting, however, we were able to complete the job using only a single sheet. And when you’re making parts from a higher-priced material, the cost difference between one sheet and two can be significant!

3. Nesting gets you more parts for less

Here’s a common scenario: A customer orders 50 flat parts, which we lay out in a nested configuration. Once the patterns are nested, we find that there’s enough room on the sheet to fit a few more parts; let’s say instead of 50 unnested parts, we can make 60 nested parts.

At this point, we reach out to the customer and offer them a custom “nested price” for the additional 10 parts. They already own the sheet material; all they’ll pay for is the extra machining time. With a very small increase in their total order price, our customer will now receive 20% more parts from the same quantity of material.

Nesting Photo #2

Or, in the case of part designs like the one in Photo #2, nesting would allow us to provide a customer with 100% more parts per sheet. The unique design of these flat parts allowed us to nest six parts on a single sheet when only three would have fit unnested!

If your part design includes complex features that can’t be completed on the router, our CNC router service experts will first cut the blanks; then, our milling pros will machine the intricate details.

Get Nested Parts at Accurate CNC Services

Are you interested in getting as many parts as possible from your sheet material? Let us know, and we’ll gladly provide a quote for your design’s nested quantity and price.